Value Engineering & Value Management

- the genes of Krehl & Partner

The competitiveness of a company depends essentially on the competitiveness of its products. However, this can rarely be achieved by low prices alone. It is necessary to develop a product for the customers that exactly meets their requirements – and at a reasonable price. This requires a comprehensive approach that works along the entire supply chain and ultimately creates products of value.

At the beginning of the supply chain there is the question of the right markets and customer groups and their requirements. On this basis, the customer benefit of the products can be optimised in a targeted manner. This can be achieved through new product features – also in combination with pricing – or through new, innovative products that offer new incentives and values for the customer. A systematic, goal-oriented approach is indispensable for a company to gain these competitive advantages.

VA/VE/VM is a proven methodology that exactly reflects this described approach and supports companies in their processes.

Our service

- Selection of the right projects

- Market research and requirements analysis

- Review of the cost situation of products

- Function analysis and function cost analysis for the as-is and should-be state

- Targeted idea workshops and input of own solutions

- Evaluation of ideas and focusing ideas into different scenarios

- Planning and monitoring of the implementation phase

Your value

- Concentration on a few projects that have an impact on EBIT

- Focus on key markets and customer groups

- Understanding of the product by all parties involved

- Reduction of variable manufacturing costs between 5-50%

- Reducing development times by up to 25%

- Creating communication and transparency and thus supporting the right decisions

- No waste of found measures

- Increased competitiveness

Are you interested in a first consultation or do you have any questions about VA/VE & Value Management?

VA/VE & Value Management - Basics and Terms

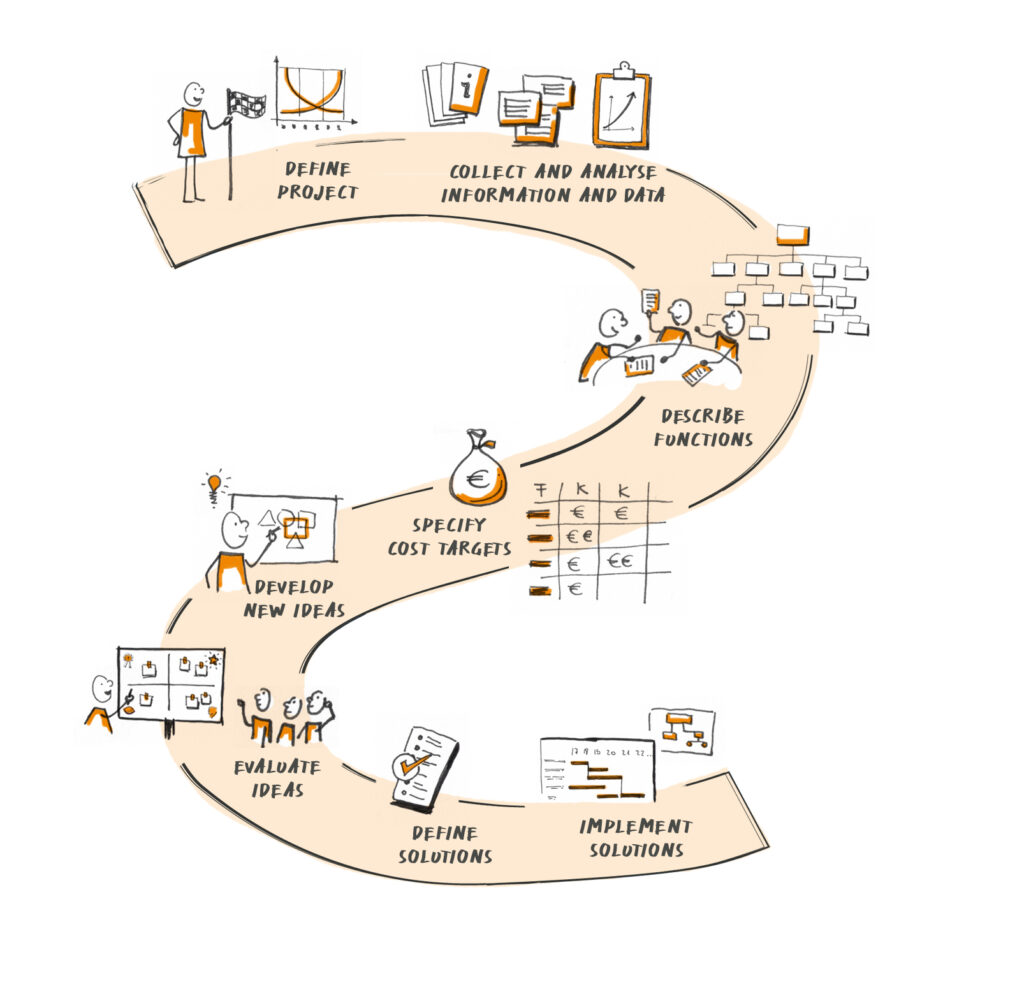

VA/VE serves the development and improvement of products, processes and services. Depending on the status in the product life cycle, three areas of application can be distinguished:

- Value planning,

- Value Engineering and

- Value Analysis.

The classical VA/VE initially saw itself as a pure method for cost reduction. In the course of time, value analysis has developed into a universal method for various tasks with a holistic approach, whereby the value concept always takes centre stage.

Characteristic for the VA/VE are:

- the function- and value-oriented way of thinking

the holistic approach, - the strong involvement of people,

- the interdisciplinary teamwork,

- the application of creativity techniques,

- the interaction of methods and tools including external and internal environmental factors,

- the systematic approach according to a work plan and

- the application neutrality.

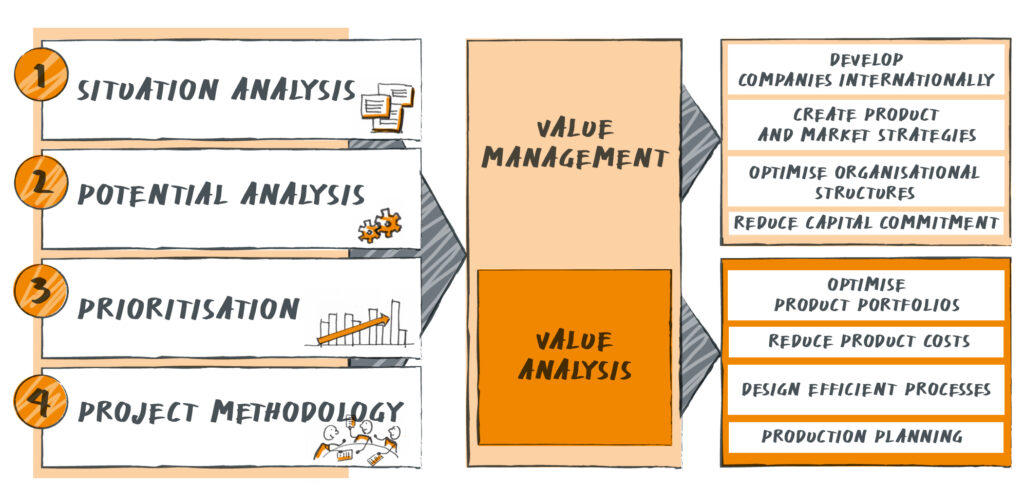

A further development took place in the 1990s:

From a cost reduction method to a problem-solving system that is holistic from a company’s point of view, the Value Management. This holistic, cross-divisional strategy is characterized by a variety of usable methods and tools as well as a strategic approach.

The Value Management toolbox

The Value Management toolbox offers various methods for using these in a targeted manner. VA/VE is not replaced, but is an essential method in value management:

Origin of VA/VE/VM

In 1947, General Electric commissioned the purchaser Lawrence D. Miles to develop a method for dealing with the shortage of materials after the Second World War. Until then, purchasers were often unable to procure the required materials or components. So, Miles asked himself what function the required component had and developed alternatives. For example, a screw has the function of “connecting parts”, but in the case of wood, a nail also fulfils this function. Interestingly, this approach revealed that the new alternatives also offered more cost-effective solutions.

By 1951, Miles and his colleagues had developed a systematic approach that focused on cost-effective product design by identifying and reducing avoidable costs. This methodology for cost reduction and value enhancement was called “Value Analysis/Value Engineering”.

Prof. Hermann Krehl, who learned about VA/VE from American pioneers and users at his former employer Bosch, recognized the importance of the methodical approach for the German economy and founded the management consultancy Krehl & Ried in Karlsruhe in 1969, which was renamed Krehl & Partner in 1975.

Standards and guidelines

In order to do justice to the high importance of VA/VE, guidelines and standards have been developed not only in Germany (DIN, VDI), but also at European level (EN), which create a common understanding of the terms and implementation of the methodology, for example:

- VDI 28xx, such as 2800, 2801, 2803, 2807

- Value Management; EN 12973:2020

Success with VA/VE/VM

Reduced costs

In practice, the reduction in manufacturing costs is between 4% for largely optimised (mass) products and 50% for customer-specific products.

The average from about 3,500 value analysis projects is 20-25%.

Shortened development time

The reduction of the development time is in the range of 25-50% if integrated early on.

This aspect is becoming increasingly important with shorter product life cycles and rapidly changing markets.

Increased functionality

The product has more, or better functions or unnecessary functions are eliminated.

This leads at the same time to an increase in customer benefit.

Increased competitiveness

Alignment with trends, such as environmental compatibility and sustainability, current design or marketing strategies for tapping into new target groups, etc. can increase competitiveness.

Better communication

The interdisciplinary teamwork promotes communication between the individual departments. These positive experiences also have an impact outside the project team and after the project is completed, they continue to have an impact within the company.

Short payback period

The payback period is an indicator for the success of a VA/VE/VM project. For most VA/VE/VM projects, it is about 1 year, for some even less – very specific to industries and projects!

More efficient VA/VE through the use of software

If you want to anchor VA/VE as a sustainable instrument in your company, then you need the right tool for this. Krehl & Partner has developed the software solution VE Master for you together with NWIS.net, in order to provide you with a powerful software for methodical support, which is based on long-standing proven procedures and meets the latest security standards.

Good reasons for using the VE-Master:

- Partial automation of your VA/VE projects through the efficient use of recurring information and project steps using a database software

- The knowledge base helps you to directly call up ideas from current and past projects, check them for their usability and, if necessary, integrate them into the project to be worked on.

- Simple project management through support in the structuring of projects and workshops, standard reporting and step-by-step guidance through all process steps.

- Overcomes borders through better collaboration throughout the entire company, even globally, based on a knowledge database.

- Supporting the adherence to the project goals by pushing the idea workflow, assigning tasks and deadlines and tracking their processing

- Effortlessly manage tasks, results, deadlines and responsibilities

- Specific access permissions enable user-defined rights and controls.